The Keymark Timeline

The Keymark Timeline

Kasson & Keller Founded

Kasson and Keller is established in Fonda, NY by William Keller, Sr. and Austin Kasson as a distributor of energy saving home improvement products.

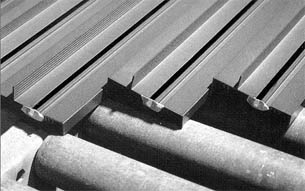

K&K Begin Storm Products

K&K begins manufacturing lines of aluminum storm windows and storm door products to supply the growing distribution business.

William Keller jr takes over

Upon William Keller's retirement, Keller's son, William L. Keller Jr., assumes control of Kasson and Keller.

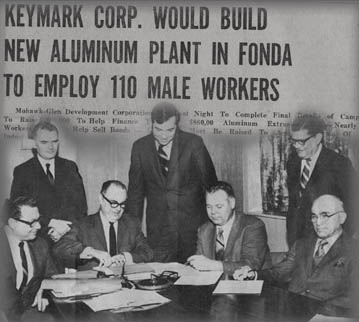

Aluminum Extrusion Plans Begin

Identifying a need for employment in Montgomery County and a reliable source of aluminum for the growing Kasson & Keller, William Keller Jr. works closely with the Montgomery County economic development commission on plans to establish an aluminum extrusion plant.

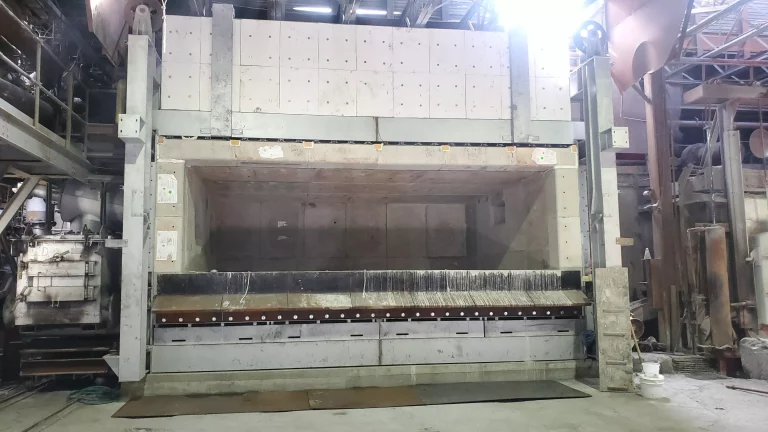

Construction on the Aluminum Facility Starts

Funds are raised by the sale of investment bonds to the community (payable in 10 years) to finance construction of the Keymark aluminum extrusion facility. The plant includes a cast house, 1,650 ton 6" extrusion press, a 16 foot vertical paint line and a hard coat anodizing facility.

Construction Completed

Construction is completed and the Keymark Corporation begins production, bringing 110 jobs to the county.

New Press Added

With a growing customer base and an increased demand for aluminum products an 1,800 ton 7" press is added to the facility, bringing employment levels to over 200.

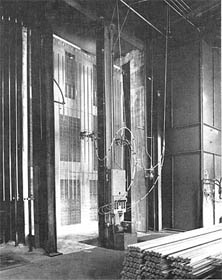

Vertical Paint Line Installed

A more modern, high volume, vertical paint line is installed to replace paint line I. In 1997, a new fully incinerated vertical paint line was installed to replace this 1971 installation.

Thermal Break Added

Keymark installs first thermal break line to supply thermally improved extrusions.

Bonds Repaid

Keymark buys back all mature bonds issued in 1965 to the community, at full value.

Further Expansion

A decision is made to undertake another major expansion to meet customer demand. The opportunity to supply more material to the storefront, heavy commercial window and curtain wall market leads to the installation of a 2,500 ton 9" press and a 25 foot vertical paint line for the application of high performance paints. Employment level jumps to over 350 people with the implementation of the new equipment.

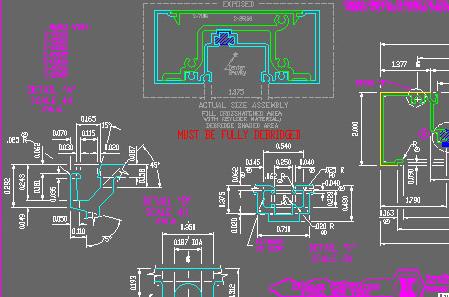

Die Manufacturing Added

New engineering technologies allow computer aided die design. Keymark begins manufacturing it's own extrusion dies.

Anodizing Capabilities Added

With industry demand increasing for high quality, 2-step (architectural) anodizing Keymark undertakes the next major expansion. A state of the art anodizing line is designed for installation in a new 60,000 square foot facility to replace the original line installed in 1965. Also included is a high tech Azon thermal break line.

The Tradition Continues

1988 sees the unfortunate death of William Keller Jr. at the age of 62. William Keller III is appointed President/CEO and James Keller appointed Executive Vice President. Control of the Keymark/Kasson & Keller organization passes onto the third generation of the Keller family.

Anodizing Production Begins

The newly constructed anodizing facility begins production. Keymark becomes one of the largest vertically integrated independent suppliers of premium extruded aluminum shapes in the United States.

Production Expands

In an effort to meet the continued demand for high quality extrusion from the Fonda plant, the latest major expansion is undertaken. An 8" 2,200 ton press is added to the facility along with a modern 18' vertical paint line to replace the 16' line. To accommodate the added extrusion production capabilities many other departments go through major reorganization/design. The addition of 50,000 square feet of production space allows for better material flow and organization of finished goods in the plant. Employment jumps to over 600.

Keymark Expands Into Florida

Due to increased demand for Keymark products in the Southeastern US, Keymark of Florida is established to meet demand. Constructed in sunny Lakeland in central Florida, the 100,000 square foot Florida facility comes on line with a state of the art 2,000 ton 7" press (press I) and a horizontal paint line with 40 foot capacity, creating over 100 jobs in Lakeland.

Full EPA Compliance

An incinerator/afterburner is installed on the 18' vertical paint line in Fonda. This addition brings the line into full EPA compliance. The incinerator allows high performance coatings (fluoropolymers) to now be applied on both the 25' and the 18' paint lines.

2nd Press Added In Florida

In 2001, Keymark broke ground in the Florida Operation for a second extrusion press. This brand new press is fully automated and equipped with a state-of-the-art conveyor run-out table and automatic stacker. Thus, the extrusions are never touched by hand until they exit the age oven...eliminating press scratches, dents, and handling damage.

Azon Azo-Brader Production

In 2003, we added a new Azon Fill & Debridge machine to service the fenestration industry in our Fonda, NY facility as well as the Lakeland, FL plant. The equipment is equipped with PLC controls and the patented Azon Azo-Brader to ensure optimal adhesion of the polyurethane and eliminate the opportunity for dry-shrinkage.

Powder Coat Paint Operations Added

In our efforts to remain the leader in the Building and Construction Markets, Keymark made some major capital investments for the future by the addition of a 40 foot horizontal powder coat line to our Lakeland, FL operations. The line is equipped with chrome pretreatment to ensure our customers the highest quality pretreatment available today in the industry. Other investments included a state-of-the-art "thermal strut" operation in our Fonda, NY facility to give our customers options as to thermal enhancement and flexibility in finishing for their fenestration products.

New Fenestration Equipment

Keymark installs new thermal strut equipment in its Fonda, NY facility to continue our leadership position in the fenestration industry. Thermal strut is a new product introduced into the U.S. for the fenestration industry, which allows for increased strength and performance, as well as multiple finishes on the same assembled section for window and curtain wall systems. This new equipment can handle assemblies up to 14 inches in width.

New Packaging Line

A new semi-automated packaging line was installed in 2007 in Fonda, improving packaging & consistency to our customers. The new line lowers banding dents and need for excessive wood blocking, which is the primary cause for shipping damage. As a result, Keymark customers are ensured of receipt of extrusions in the very best of condition ready for their use.

Thermal Roxidizers Installed

Thermal Roxidizers were installed on the 40 foot horizontal paint line in the Lakeland, FL facility. These Roxidizers allow Keymark of FL to start painting superior Kynar based high performance paint coatings, which allows our customers to achieve AAMA 2604 & AAMA 2605 performance standards. These Roxidizers eliminate 98% of the V.O.C.’s (volatile organic compounds) emitted into the atmosphere, keeping in line with our Green Initiative.

Press 4 Upgraded

Press # 4, which is the 8” extrusion press in Fonda, NY, receives an upgrade to the existing equipment. This upgrade included a belt handling conveyor system, finish cut saw, and new pullers for the press. These upgrades dramatically improved the finish quality of extrusions to our customers and reduced internal scrap.

Third Press Added in Lakeland, FL

In 2010, Keymark added to our arsenal of presses a 3,000 ton UBE press that is capable of producing extrusion shapes up to 14" in circle size. The new press was installed in our Lakeland, FL facility and an additional 106,000 square feet of production space was added to the existing 145,000 square foot operation to accommodate the press. The new press includes state of the art water quenching capabilities and handling system and is accompanied by an automatic stacker to accentuate it's capabilities. Keymark Corporation now operates 7 extrusion presses in NY & FL ranging in circle size from 6" to 14" capabilities. Total production space now reaches 566,000 square feet.

Press 3 Upgraded

In 2011, Keymark Corporation of FL upgraded the UBE 3,000 ton press, capable of producing shapes up to 14" in circle size, with a new Granco Clark billet heating furnace. The new fully automated gas fired billet furnace is equipped with PLC controls providing unmatched billet heating uniformity and improved thermal efficiency. Keymark Corporation opens an Operations/Training conference room with the latest video conferencing and audio/visual equipment for presentations during meetings. Keymark installs a new fully automated off-loading conveyor system to the high-performance paint line in NY. The new conveyor greatly increases the quality of painted extrusions by maintaining separation between extrusions as they come off the line. Keymark is one of only two paint lines in North America incorporating this new technology.

Quality Management System Implemented

In 2012 Keymark Corporation was proud to successfully implement the ISO 9001:2008 Quality Management System specification. Continuing to meet this specification helps ensure the highest quality product to our customers as well as the best and most efficient work environment for our employees. This is not a one-time qualification, but an ongoing process that is reviewed annually in order to continue to meet this specification and provide the best service to our customers.

Lakeland, FL Press Upgrades

In the Spring of 2014, Keymark invested $2.6 million in an extrusion press upgrade to our current large press in Lakeland, FL. The aluminum extrusion press, capable of producing shapes up to 14" in diameter, was equipped with a new state-of-the-art water quenching system, a double puller, and a Kevlar belt conveyor handling system as well as improved cutting equipment. The upgrade improved its water quenching capabilities, production efficiencies, and surface finish quality as well as its cutting capabilities.

Multiple Upgrades Completed

In 2015, Keymark Corporation completed several capital projects to our Florida & New York facility. The projects included an upgrade to it's 10" extrusion press as well as a total reconstruction and addition of new equipment to the die cleaning/caustic room. The upgrade to the UBE 10" extrusion press included a hot log saw to replace the log shear previously used, new billet loader, and conversion to the press to make it a short stroke press. These upgrades will reduce overall scrap, increase the length of the extrusion run-out, and reduce the amount of billet changes and dead cycle time. Our press 1 (7" press) underwent a complete PLC control system replacement and upgrade. The completely transformed die cleaning/caustic room includes state-of-the-art die cleaning equipment that is more environmentally friendly, safer, and will reduce the amount of caustic chemical necessary in the cleaning procedure of the die tooling. In our New York facility, our press 3 (9" press) received a new log saw replacing the existing log shear and a new loader system to reduce scrap and improve dead cycle time.

8" Press Upgraded

In 2016, Keymark NY upgraded our 8” extrusion press with a completely new log feeding system, including a feed table, log furnace, & log shear. This upgrade will improve the billet cut length, help to achieve lower scrap, and improve overall efficiency of the press.

Vertical Paintline Upgraded

Our Fonda, NY operations upgraded our existing high performance 25’ vertical paint line. The $2.1M upgrade consisted of expanding its footprint by 3,000/sq. ft. to accommodate a new state-of-the-art stainless steel washer and latest technologically advanced pre-treatment system. The new system improves overall efficiencies and ensures our customers’ continue to receive the highest possible quality paint coatings in the industry. The NY operations also underwent an extensive upgrade to the 9” extrusion press. It included a new Kevlar belt handling system, upgraded head & tail stretchers, press saw, double puller with movable saw, log oven, upgraded hydraulics on the container, new PLC controls, and added an air & water quench system. The upgrade resulted in reduced cycle time, reduction in press scrap, as well as improved overall efficiency and quality.

Press 1 Upgrade

The 6” press in Fonda, NY underwent a $ 1 million handling system upgrade that included a log infeed table, 5 zone furnace, log shear, & horizontal loader assembly.

Press 4 Upgrade

The 8” press in Fonda, NY underwent a $ 2.4 million full handling system upgrade that included: Hot saw, new cooling system, dual pullers, chip collectors, belt transfer and cooling conveyors, finish saw & electrical control system.